Process Stream

Streams in Dynamics Mode

Streams behave similarly in dynamics mode as they do in steady state mode. But when a new stream is created or connected to the flowsheet in dynamics mode, it is typically initialized with starting values. Streams must have initial values when the integrator is started. The dynamics assistant can be used to easily fix streams which somehow do not have proper initial values.

Stream values are updated only when the user interacts with directly with the stream, or while the integrator is running. Changing a unit operation will typically not change any stream contents until the integrator is started.

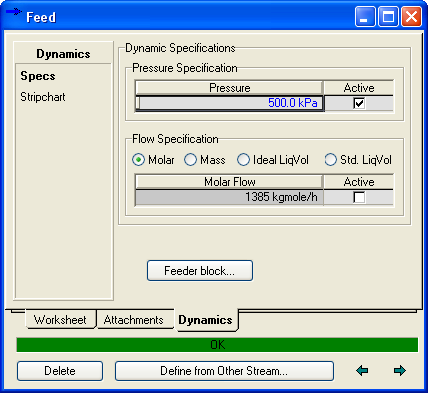

The flow rate and pressure of a stream are either specifications (set via check boxes on the Specs tab of the stream), or are determined by solving a subset of simultaneous equations from the model, as explained earlier in the basics.

The stream conditions (temperature, enthalpy, phases etc.) are determined by the stream itself, or by the equipment to which it is attached. If a stream is a product attachment (outlet) and has a positive flow (greater or equal to zero), or it is a feed attachment and has a negative flow (less than zero), then its contents are determined by whatever unit operation feeds into it. The stream phase fractions will also depend on that unit operation. The values may depend on the liquid levels inside that unit operation and the stream nozzle elevation and diameters, as explained earlier in the basics. The stream phases may or may not be in equilibrium.

If a stream has a positive flow rate and there is no unit operation upstream of it, then its conditions and composition are as determined by the stream specifications (on the conditions and composition pages of the stream view). These can be set while the integrator is running or while it is stopped. If a product stream attachment, which has no unit operation downstream connected, has a negative flow rate, then its conditions and composition are also set by specifications inside the stream. So a product stream with a negative flow rate behaves exactly like a feed stream. And a feed stream with a negative flow rate becomes a product.

Note that during the simulation a stream's flow rate may change direction. If a feed stream has a positive flow rate, reverses flow, and then changes back to having a positive flow, its composition and conditions are determined by the stream's feeder block. A feeder or product block is present in any stream that is not connected at both ends. Think of the feeder block as an infinite vessel. Its contents does not change if material flows into it, and it always provides the same predetermined contents to streams that flow out of it.

If the user changes conditions in a stream (e.g. specify a different temperature or composition) then the feeder block will update its values with those from the stream. The user can also explicitly set values inside the feeder block and export those to the stream.

Note that, while not possible in steady state, it is possible to export composition values from a spreadsheet to a feeder block or stream in dynamics mode. The feeder block will automatically detect full or partial composition specifications and trigger an update in the stream, depending on its flow rate. Condition specification sent to the feeder block. The feeder block will then pass them to the stream, as and when appropriate.

Since stream flow rates are determined from a network of equations, composition specifications should be on a mole or mass fraction basis for example, rather than on a flow rate basis.

The conditions page of the stream has an "Initialize Stream Conditions" button. When pressed, it allows the use to specify any stream conditions (temperature, enthalpy etc.) regardless. The stream will flash (recalculate) if a value is specified. This can be used to change the contents of a steam anywhere in the simulation, if need be. Of course once the integrator starts, the stream will likely be updated by attached unit operations. But there are some rare situations where it is desirable to change a stream or perform a quick experiment.

Do note that terminal (i.e. having no upstream or downstream operation) streams typically have pressure specifications. Such stream are also typically connected to something which has a pressure flow relationship such as a valve. Terminal streams that instead are directly connected to a vessel can also have a pressure specification (e.g. a vessel vapour stream which opens the vessel to the atmosphere), but only one terminal stream directly connected to a vessel can have a pressure specification. Internal (non terminal) streams generally do not have pressure or flow specification, as their flow and pressure are determined by the network equations. If a terminal feed stream is directly connected to a vessel, it will typically have a flow rate specification.

Do note that terminal feed streams without a pressure specification may continually flash (recalculate) as the pressure changes. This can be costly in some cases. This situation can be avoided by inserting a valve and specifying its upstream pressure instead of the flow rate and using the valve to regulate the flow rate.