Petro-SIM 7.3 Changes to Refinery Reactors

Petro-SIM 7.3 introduces key improvements and added capabilities to the Reactor Suite to keep up with the demands in the industry, including major technical improvements to our hydroprocessing reactors, delayed coker reactor, and C5/C6 isomerization reactor.

Key Highlights

- Integrated EBR-SIM into HXX-SIM suite, with corresponding kinetics, fluid dynamics, catalyst handling, and configuration support improvements

- New overall HXX-SIM calibration algorithm for improved usability and convergence for complex configurations

- DC-SIM Kinetics Revamp, including improved feed characterization, enhanced reaction network, and better feed quality response and overall model performance and robustness

- ISOM-SIM Kinetics Revamp, including enhanced, kinetics-based reaction network, improved mass and heat balance, and revamped calibration algorithm with auto-tuning capabilities

- Usability improvements - Enhanced HXX wizards, Improved DC Calibration layout and documentation, Improved AROM GUI readability and key parameters exposed

- FCC-SIM, Renewable Diesel DHTR-SIM technical updates

HXX-SIM

EBR-SIM

- High fidelity ebullating bed SIM Suite reactor model, with fully functional capabilities including:

- Resid conversion kinetics, continuous catalyst makeup & removal, sedimentation and hold up calculations

- Traditional calibration and full range of tuning factors

- Prediction of feed property effects, reactor operating condition effects, recycle stream effects

- Inclusion of interstage separators to remove light ends and calibration to plant specifications

- Now supports configurations of 2 reactors with interstage stripper and up to 3 reactors in series

- Now able to accumulate metals on catalyst (MOC) for each reactor individually and can calculate and report current and EOR catalyst ages based on MOC

Updated HXX-SIM Calibration Algorithm

- Improved calibration usability and performance for cases that had long convergence times (more complicated configurations) or would not converge despite good calibration data

- Removes the need to use guesses of intermediate stream properties and replace these with known catalyst properties and measured product properties

- Removes need for user to iteratively guess H2 consumption by reactor to achieve convergence

- Old convergence method maintained for easy migration

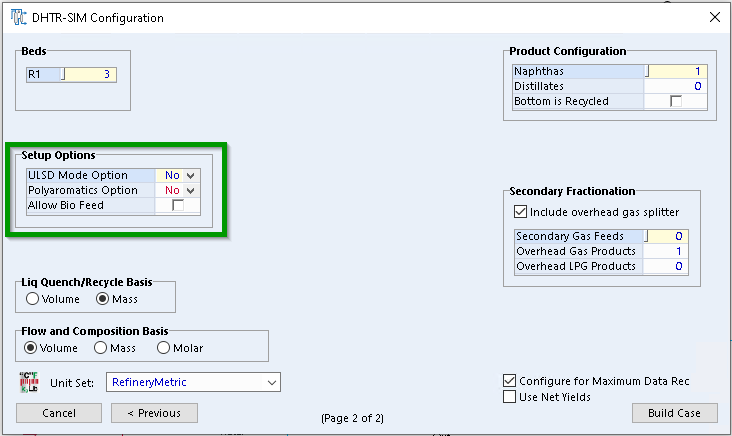

Renewable Diesel Mode in DHTR-SIM

- Updates to technology based on feedback on 100% bio feed processing

- Improved calibration convergence for 100% bio feed cases (with recycles)

- Better accounting for liquid quench effects

- Update total H2 consumption and heat balance effect from olefin saturation

Usability - Enhanced Wizards and more

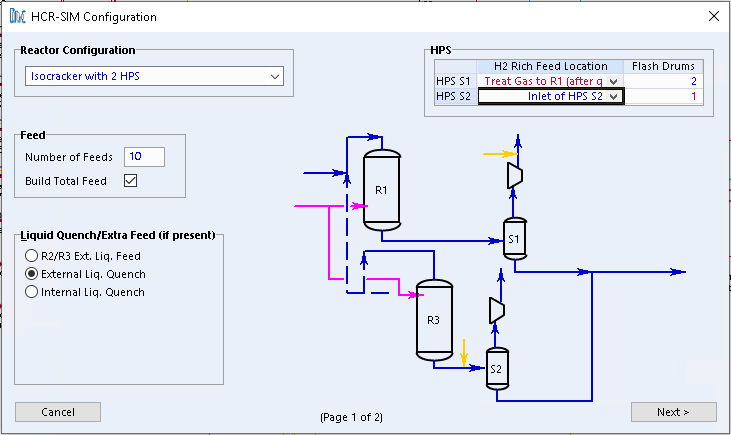

- Wizard updates for all HXX-SIM modules

- Overall improved UX to save users time and help guide new users on available functionality and recommended setup

- PFD added with interactive quench and H2 rich feed visualization

- Added relevant options/modes at wizard level for proper initial setup

- Updated, more specific defaults for each reactor-type: number of products and product configuration

- Error messaging - more relevant error messages will be prioritized to identify calibration failures more easily (avoid too many messages causing more useful messaged to be suppressed)

- Updated calibration status monitor to show full range of reactions (including renewable diesel, if applicable)

DC-SIM

Updated Feed Characterization and Reaction Network

- Detailed Feed Characterization with Ca, Cn, Cp and Ca ring breakdown for each pseudo component

- Kinetic rate constants now a function of molecular structure

- Improved fundamental basis for handling effects of feed quality and operating condition changes on reaction kinetics

- Include soft coke lump to model the coke induction difference and effect of miscibility

- Remove any solution discontinuities due to feed quality changes

- Improved overall model performance with better calibration matching and enhanced tuning capabilities for yield responses

FCC-SIM

- Improvements for High Severity FCCs

- Updated C5 yield shifts for propylene-selective ZSM-5

- Improved 2 riser convergence

- Introduced ZSM-5 deactivation as tuning factors that consider replacement rate, vanadium, and high temperature effects

- Added Ca as a refinery assay property and incorporated effect of hydrothermal deactivation due to Ca on catalyst

ISOM-SIM

Updated Reaction Network and Calibration Algorithm

- Updated, more fundamental kinetic-based isomerization reaction network and side reactions (less temperature dependent correlations)

- Enhanced heat and mass balance to include isenthalpic flash calculations to determine temperature profile

- Introduce sequential calibration algorithm with auto-tuning capabilities instead of relying solely on external optimizer for matching component yields

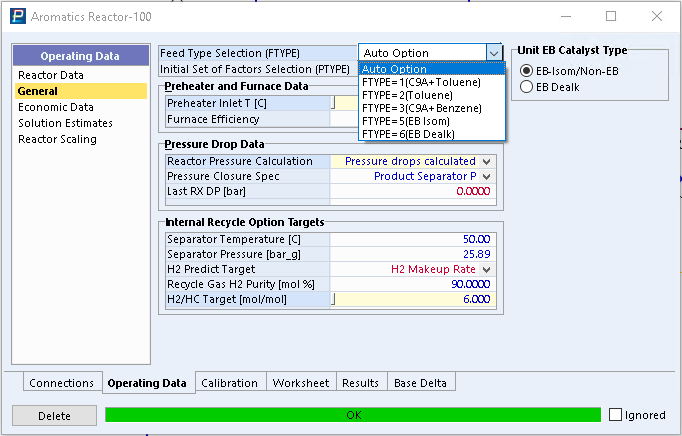

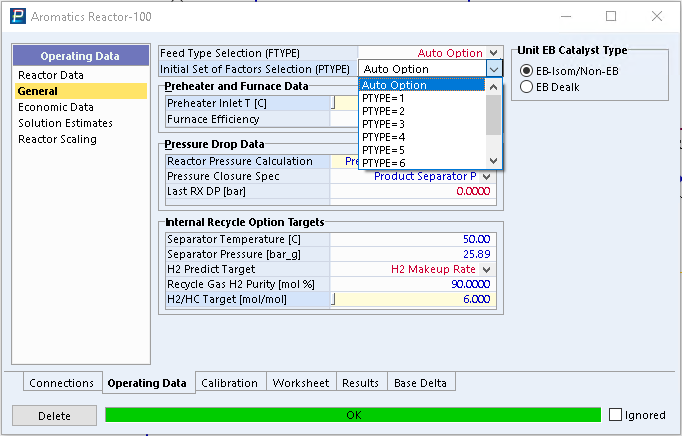

AROM-SIM

Usability Updates

- Exposed FTYPE and PTYPE options which control kinetic parameter defaults during calibration based on feed composition, catalyst type, and process conditions (H2/HC and inlet T)

- Improved GUI readability and layout