Tray Section

Introduction

The tray section models a sequence of stages, each with a volume, liquid level, and flows between stages. Stages can individually flood or be run dry.

Sizing

The volume determines the amount of material on each stage, so it is important. Also, the weir length and height generally strongly influence the amount of liquid on each stage. The same values are used for all stages in the section.

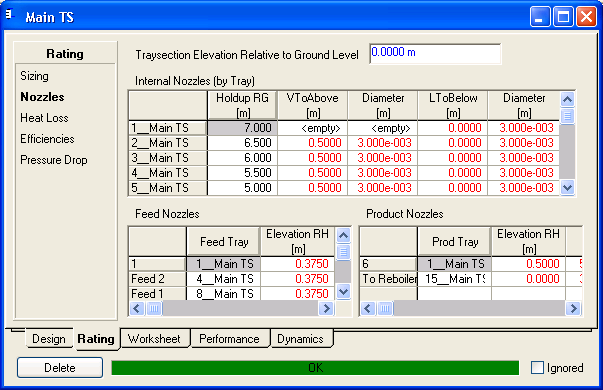

Nozzles

The elevation of the entire tray section can be set as can nozzle elevation and diameters for streams between stages and external streams. Nozzles for internal streams are usually left to the default elevation and diameter. For feed nozzles the elevations are sometimes changed so as to influence static head or the phases that will be withdrawn in the case of flow reversal.

Heat Loss

Tray sections generally lose heat to their surroundings and in some cases this can have a significant impact. Various degrees of detailed heat loss models are hence available.

Efficiency

Tray efficiencies generally set the stage recycle efficiencies (see | the basics) and can be used to model non equilibrium stages. While these can deliver similar results to steady state, the definition and values can differ. Tray sections are usually modeled as a series of ideal equilibrium stages.

Component efficiencies are not supported in dynamics.

Hydraulics

The page shows the tray static head contribution, the height of liquid over the weir, as well as the dry hole (vapour frictional) pressure drop.

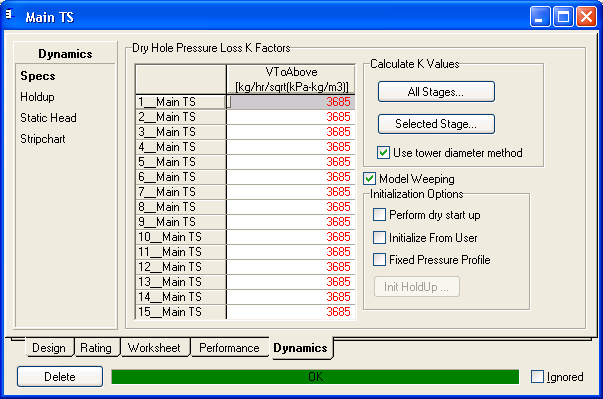

Specifications

Each stage requires a K value, which links the vapour flow rate from one tray to the tray above it to the dry hole frictional pressure loss. The liquid flow rate is determined by whether the liquid height is higher than the weir height, or whether the tray is weeping.

Fixed Pressure Profile can be used to model very simple columns where changes in the pressure profile are not of interest. The stage pressures are all fixed.

Dry Startup and Initialize from User can be used to initially fill a tray section with vapour only or user chosen contents. Note that the dry startup option can be rechecked if the integrator is not running, allow the tray section contents to be readily emptied.

Static Head

For trayed sections, static head contributions are often essential for a realistic model and pressure profile, even if static head contributions might not be desired in the rest of the model. It can be turned on specifically for tray sections only, though most models have static head turned on in general.

< Flowsheets and Columns | Index | Recycle >