Pump

Introduction

The pump is frequently used to provide a driving force for moving liquid.

Curves

Steady state supports a pump curve as found on the Design, Curves page in the view. However, dynamics mode needs to support a more complex set of curves, as found on the Rating, Curves page. This is because modeling pump startup and shutdown requires a more complete set of curves.

If pump curves are used it is generally recommended that several curves (at least three or four) be adding, covering the range of speeds across which the pump may operate or go through. The code will extrapolate beyond the curves values, but this can be problematic in some situations. A healthy set of curves provides good results, since equations are contributed to the simultaneous solution for the curves.

NPSH

Net positive suction head curves can be provided so that the required pump NPSH can be determined. If the NPSH available is less than the NPSH required, then the pump cavitates. This is modeled by varying the density in the pump equations. NPSH curves do not contribute equations to the simultaneous solution.

The NPSH available is calculated from the flow velocity using the feed nozzle diameter. It is equal to the inlet pressure minus the vapour pressure in terms of height plus the velocity head.

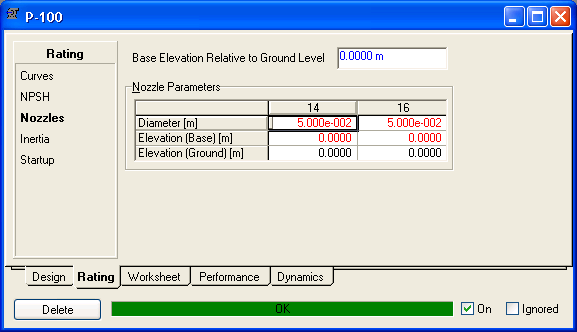

Nozzles

The feed nozzle diameter is used in NPSH calculations. The pump elevation is used to determine static head contributions. The pump nozzles are typically left to be at the same defaulted elevation as the pump, but can be adjusted to model additional elevation differences without adding extra equipment.

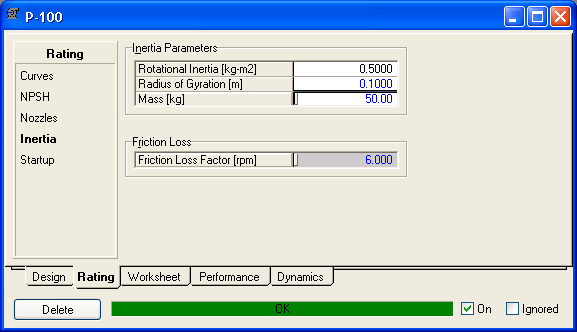

Inertia

Modeling inertia can be helpful in realistic pump modeling and tends to make it easier to model pump startup and shutdown. Both inertia and friction result in a small duty loss in the pump.

Startup

The typical operating low is used by the pump to make some minor adjustments to densities and duties at very low flow rates (e.g. to avoid using a vapour density right at startup). An approximate or default value will suffice in most cases.

Performance

The pressure head is the total pump pressure change express as a height by using the feed density. The velocity head is the difference between the product and feed velocity heads. The two velocities are calculated using the nozzle diameters. Note that the total head also includes other contributtions such as the frictional pressure change.

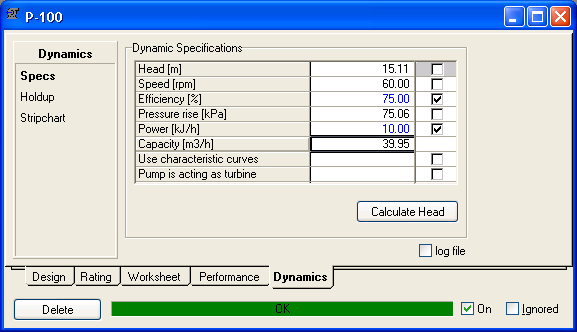

Specs

This determines what equations the pump contributes to the simultaneous equation network. By default the efficiency and power are specified. If Use characteristic curves is checked, then only one other specification (power is strongly recommended) is typically used since two equations are contributed for the curves.

Pump is acting as turbine can be used to model a turbine which generates power. The pump equations are still mostly the same, except the sign of the head is changed (since the pressure gradient is reversed), and the inverse of the efficiency is used.

Note that the pump can of course be switched on and off. If the pump has a speed specification, then this is done by ramping the speed up and down. If the power is specified, then the power is ramped up or down.

< Tee | Index | Compressor and Expander >