PFR Plug Flow Reactor

Introduction

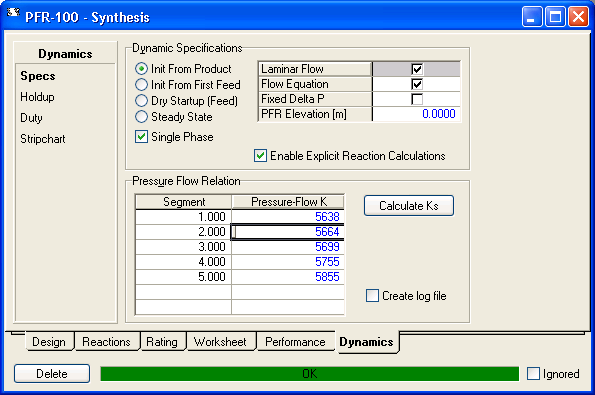

The PFR is configured and set up the same way in dynamics mode as it is in steady state mode. However, the links between pressures and flow rates are set on the Dynamics, Specs page.

PFR Dynamics

When a PFR is used for the first time in dynamics mode, the holdup volumes need to be initialized with some starting content. The options are:

- Init From Product which is the recommended default. The reactor is initially filled with product.

- Dry Startup (Feed) in which case the reactor is initially filled with feed material, but vapour only.

- Steady State can be used if the case was solved in steady state mode and now being used in dynamics mode.

As for pressure and flow specifications, the options are Flow Equation or Fixed Delta P. It is recommended that only flow equation be checked as this establishes a natural link between flow and pressure gradients. Fixing the pressure drop can be used in simple cases but in large models it can result in unrealistic behavior such as flow against a pressure gradient.

If Flow Equation is checked, then a k value needs to be specified for each segment. This k value is used in the equation which links the inlet flow for that segment to the frictional pressure gradient. Calculate K's can be used to calculate these k values from the current pressure gradient, density, and flow values.

Laminar Flow is checked by default and changes the pressure flow equation solved in the network to be simpler and more consistent with laminar (lower) flow conditions. In such cases the flow is proportional to the pressure gradient rather than the square root of it.

Single Phase can be checked if the contents is all vapour or all liquid. This will speed up reaction calculations, and should be checked when applicable.

Enable Explicit Reaction Calculations can be checked to use a faster method of calculating the reaction results. In some rare cases this may cause instability, but is generally preferred for speed.

Lag Rxn Temperature (visible in older views) is not used.

The duty option can be set similar to what is done for the vessel. The duty is typically divided and applied equally to the individual segments.

The number of segments can be changed while the integrator is not running. But if segments are added, K values typically need to be provided for those segments. While additional segments will result in a truer plug flow result, it will also slow down the model, as each segmented is flashed and reacted separately.